As a Manufacturing company, DTech Service integrates individual parts into assemblies that provide process solutions for our customers. Utilizing a variety of manual, semi-automated, automated production and in-process testing, manufacturing supports economies across the globe with a wide range of products. In industries ranging from Municipal, Commercial, and Industrial to food and recreational sectors D Tech Service continues to evolve with advancements in technology and automation. D Tech Service’s turnkey manufacturing capabilities and network partners allow us to generate high-quality products for process control systems. Learn more about our services.

Production

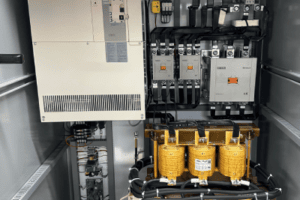

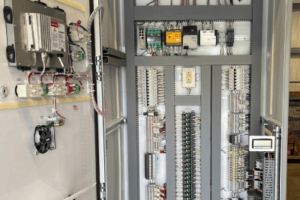

Outsourcing your manufacturing needs to D Tech Service allows you to focus on your core business while we supply scalable solutions and reliable products. We adhere to ISO 9001:2015 and UL 508a standards to ensure high-quality, well-constructed variable frequency drives (VFDs), motor control panels, and more. Our streamlined manufacturing process focuses on efficiency as we aim to shorten lead times and provide punctual delivery. We also emphasize transparency in our communication with you so that you can be fully involved in each phase of production from material procurement to order fulfillment.

Industry Solutions

At D Tech Service, we offer our manufacturing services and extensive experience to provide you with comprehensive industry solutions. These include:

- Design consultations for products tailored to your needs. Our design and engineering team will work closely with you to gain an in-depth understanding of your requirements. Addressing anything from harmonic mitigation to enclosure ratings, we create quality designs that align with your unique vision and product specifications.

- Component and material sourcing. Using only UL-listed components, D Tech maintains an extensive network of trusted suppliers. This grants you the flexibility to choose the most suitable and readily available parts and materials for your VFDs and panels.

- Manufacturing processes. By employing a multitude of workmanship guidelines that outline advanced and finely tuned manufacturing procedures, our company produces custom VFDs and panels in various types and sizes, all while upholding rigorous standards of quality, safety, and UL compliance. These instructions are ingrained into our company culture, ensuring consistent adherence to high standards in our work.

- Product testing and validation. We carry out rigorous testing on our products to confirm that they comply not only with your exact specifications but also with industry quality standards and ratings. The project-specific testing process is meant to instill confidence in our products’ safe and reliable performance.

- Project documentation. The D Tech team generates and maintains comprehensive documentation on your project, incorporating everything from your product specifications and Bill of Materials (BOM) to manufacturing records and test reports.

- Real-time project reporting for maximal transparency. Our ERP system provides pinpoint accuracy in terms of knowing exactly where your project is in the production process. Our transparent project reporting service allows you to track material procurement, project schedules, production progress, testing results, and more for clear, start-to-finish communication.

- Industry and product expertise. We pride ourselves on our unparalleled technical expertise in VFDs and AC motor control products. Our team will offer recommendations on ways to optimize performance and enhance energy efficiency within your budget.

- Responsive customer support. To best assist you, our dedicated team of customer support professionals is well-versed in the technical details of our products. We respond promptly to all inquiries to cultivate a seamless customer experience from your initial quote request through manufacturing and delivery.

- Continual improvement and innovation. Keeping abreast of applicable advancements in our industry, we are committed to continual improvement and product innovation. We continue to evaluate our processes and products, looking for opportunities to enhance efficiency, quality, and performance.

To learn more about our manufacturing capabilities, contact us today.