Quality designs are the foundation of high-performance variable frequency drives, motor control panels, and related products for automation technologies. At D Tech Service, we offer advanced design, engineering, and load-testing services to create custom products that meet your requirements for efficiency, functionality, and safety.

Custom Controls and Automation Solutions

Among D Tech’s core competencies are engineering high-performance, energy-efficient solutions for variable frequency drives (VFDs) and control panels for automated systems. We design our custom products with our customers in mind, aiming to offer you seamless VFD integration into your existing systems for reliable operation.

Our experienced team will analyze your exact system requirements and facility infrastructure, then align our VFD and control panel solutions considering your performance and cost target. These solutions may include new, innovative components as we worked with you to create the best design. When appropriate, the D Tech team can assist you with retrofit packages for greater cost-efficiency. We’ve developed these packages to provide you with enhanced value and with the goal of seamlessly incorporating retrofit equipment into your existing systems.

Whichever solution is the right choice for your operation, our custom designs for VFDs and control panels will boost efficiency and performance in your operation while decreasing unplanned downtime.

VFD Load Testing

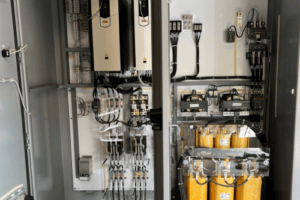

It’s critical that your VFD be able to meet the needs of your individual application. At D Tech Service, we operate a testing facility equipped with state-of-the-art machinery to provide you with the peace of mind that we’ve verified your VFD’s full load performance.

Our expert team of engineers will ensure optimal functionality under various loads, simulating real-world conditions to push your VFD’s limits and define its full potential. By partnering with us for VFD load-testing services, you help safeguard your operations, system breakdowns, unscheduled downtime, and productivity losses.

Key Features of Our Process

Our designs emphasize product quality and safety. We adhere to the ISO 9001:2015 quality management standard in every aspect of our design and engineering capabilities. Also, by engineering each of our control panels in compliance with the UL 508a standard, we meet your expectations as well as industry benchmarks for quality construction.

Prior to beginning the design stage, potential customers will be guided quoting through submittal process, and final design acceptance.

- D Tech releases to manufacturing, and testing of your VFDs or control panels before shipping the completed order

The typical submittal phase includes detailed technical drawings and Bills of Materials (BOMs), which will serve as the documentation of your product design and construction. There’s also an optional comprehensive submittal package available for when your project requires a higher degree of detail in product planning. In these cases, our engineering team will develop in-depth cut sheets and an Operations & Maintenance manual.

In the background, our engineers work closely with our trusted vendors to minimize lead times and achieve on-time delivery. For these reasons and more, we’ve maintained customer relationships averaging over 40 years of continual support.

Design and Engineering From D Tech Service

Our design and engineering team offers high-quality computer-aided design (CAD) services so that we can meet your needs, with capabilities for anything from simplistic designs to complex, technical units and systems. Our products are engineered to order in adherence to your specifications. Contact us today to learn more about our capabilities for customized designs and engineering solutions.